The toolpaths can then be regenerated by the receiver from the file containing only the parameters. Simply right-click the operation(s) and choose Clear Toolpath before saving the document. If you wish to send the file by e-mail or similar, you may want to clear the not required toolpath data from the file before sending it. You will notice that the toolpath data of machining operations can cause the size of your files to grow considerably. To remove the Inventor HSM-specific data from a part or assembly file, simply delete all operations from the CAM Browser and save the file. This Inventor HSM data remains within the file even if it is edited on a system that does not have the Inventor HSM add-in installed. The machining operations created in a part or assembly are stored with the Inventor file itself - including the generated toolpath. Restriction: Assemblies are not supported in Inventor LT. In this example, you would click CAM tab 2D Milling panel 2D Pocket. You select the first operation you wish to perform on the workpiece by clicking the appropriate icon from the command ribbon. For more information about creating a setup, see the Help topic: Setup Reference. If you do not create a setup manually before adding your first operation, a setup with default parameters is created for you automatically. A setup defines a number of general properties for a set of machining operations - including the Work Coordinate System (WCS), the stock geometry, fixtures, and the machining surfaces. Normally a machining operation, like pocketing, is started by creating a Setup.

The following example illustrates a 2D Pocket strategy which is used to remove the interior cavity of a part.

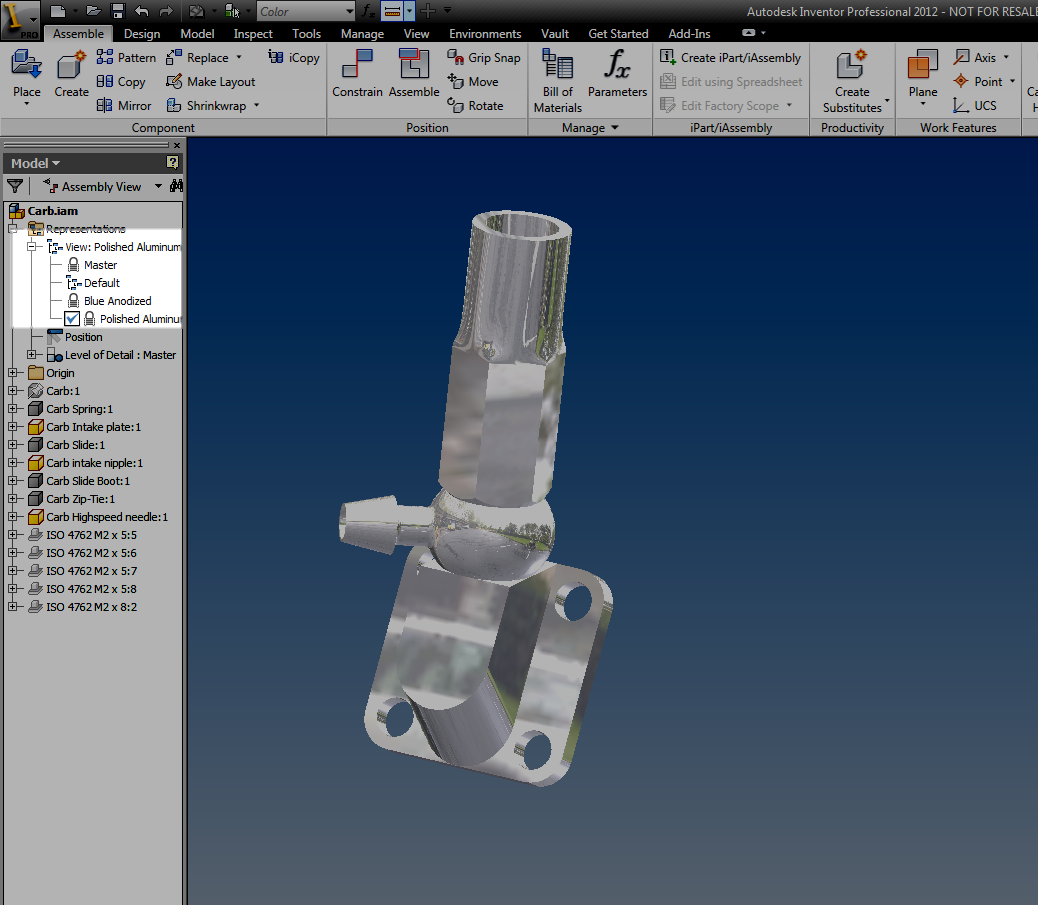

For a description of the individual machining strategies, please refer to the Inventor HSM Help topics: About 2D Machining Strategies and About 3D Machining Strategies. The type of toolpath required naturally depends on the geometry of your part. To create your first machining operation, simply select any of the toolpath strategies from the CAM toolbar. The CAM Browser lets you view and modify all machining-related data in the current part or assembly. Once a part or assembly file is loaded and a strategy selected from the CAM ribbon, the CAM Browser becomes active replacing the familiar Inventor Model Browser.

0 kommentar(er)

0 kommentar(er)